Great news, October 17, Chimicron introduced a micro-focus X-RAY inspection equipment and a micro-focus X-ray smart spotting machine, aiming to provide customers with better service and more professional purchasing experience. Since the establishment of Chipsmall, its market share has been increasing year by year, steadily rising. The two advanced equipment introduced this time will help Chimicron to move to a higher level.

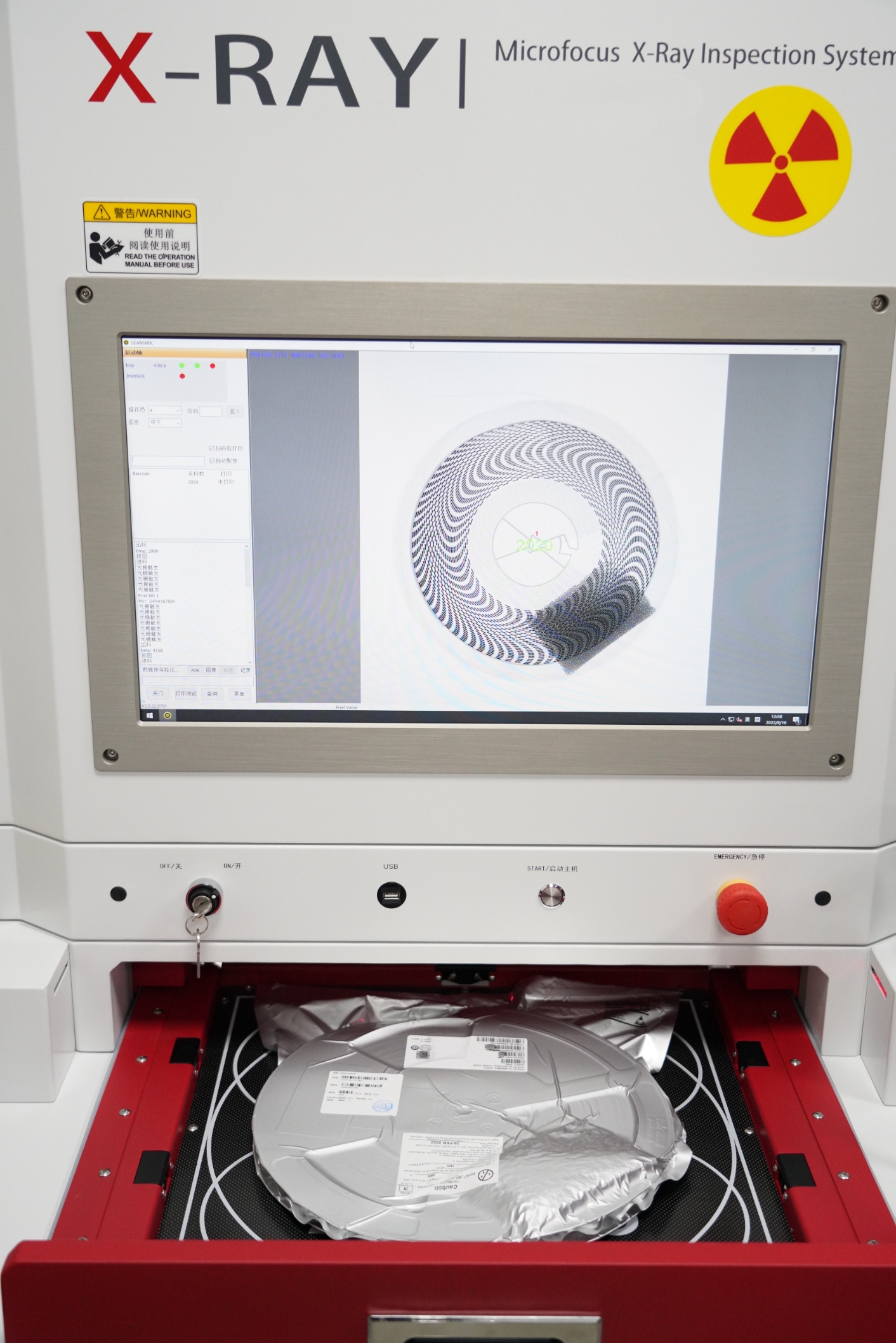

Microfocus X-RAY inspection equipment will solve the problem of over-reliance on human experience in traditional quality control, with a larger effective inspection range, improving product magnification and inspection efficiency.

It can detect defects below 2.5 microns, and the detection repeatability is high; in addition, the editable inspection program realizes CNC automatic inspection; the stage can move along the XY direction, and the speed can be divided into slow, medium, and fast (adjustment), The stage can be tilted ±45 degrees.

This X-RAY inspection equipment adopts high-resolution design to obtain the best image in a very short time, infrared automatic navigation and positioning, quickly selects the shooting position, and can easily identify the bending and breaking of the gold wire of the semiconductor package. Adopt CNC inspection mode, fast and automatic inspection for multi-point array, suitable for mass inspection. Inclined multi-angle inspection makes it easier to detect sample defects and improves inspection efficiency.

In addition, the X-ray source of the equipment adopts Hamamatsu, Japan, which has the longest life and the best stability in the world. The development of a series of flat panel detectors, the performance index is higher than that of international competitors, and the designed product life can reach 15-20 years.

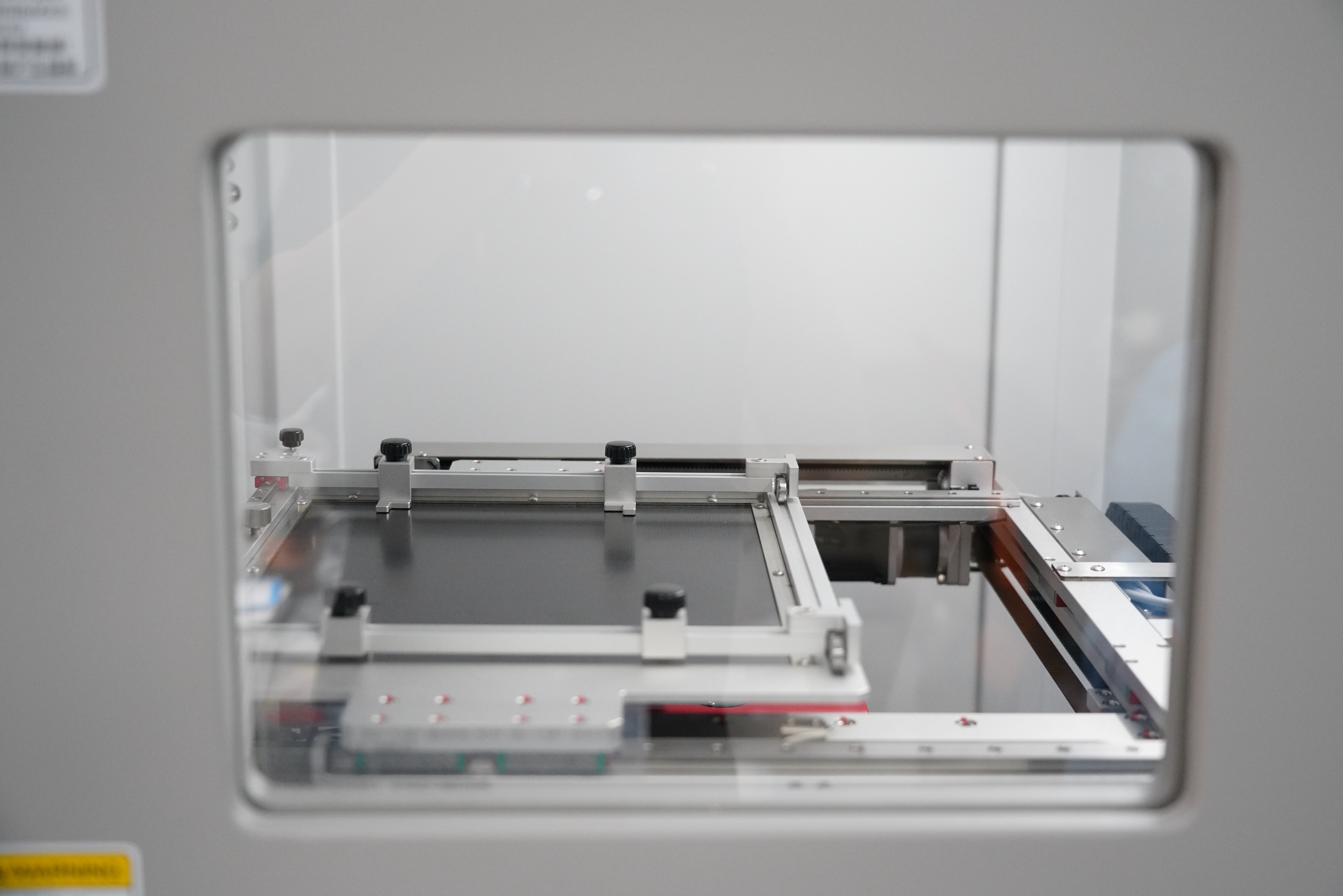

The micro-focus X-ray smart spotting machine will optimize the material ordering process. It uses the X-Ray perspective principle and algorithm software with AI functions to quickly and accurately calculate the number of materials in the discharge tray, and also has MES data uploading and automatic printing of material labels.

It adopts the first domestic material foolproof design to avoid material coding errors, which can greatly improve the shortage of materials, missing materials, missing materials, and insufficient materials, digitally manage material storage, and improve the accuracy of material inventory.

This equipment's accumulated material database is shared with all machines, with more data, more reliable and accurate material point, and can complete 4 7-inch material trays at one time. There is no need to open the packaging bag to point the material, maintain the integrity of the roll, and will not affect the moisture resistance of the roll.

It is precisely because of the strict control of the quality of components that Chimicron has been highly favored by the market and has also received unanimous praise from customers. In the future, we will continue to expand investment, establish a higher standard quality control system, and empower the upstream and downstream of the electronic components industry chain.

Chimicron has always adhered to the business philosophy of "high quality products, customer priority, honest management, and thoughtful service", and is committed to the global distribution of electronic components Goods flow to customers", escorting the security of your component supply chain.